Starting from July 1st this year, LED light bulbs and LED light fixtures sold in the Japanese market must be affixed with a circular Product Safety Mark (PSE).

See more information

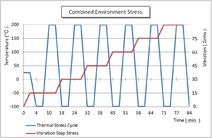

Test conditions for HALT&HASS of Yiguang Technology LED driver. 1. The samples tested by the target underwent HALT (High Acceleration Life Test) process to reveal weaknesses in their design, component selection, and/or process.

See more information

Yiguang Technology Company mainly researches and produces: UL certified LED power supply, CE certified LED power supply, CQC certified LED power supply, PWM dimming LED power supply, DC dimming LED power supply.

See more information

Entrepreneurs in the LED industry know that the LED home market is an important market for future profitability, but they have yet to conquer the field of home lighting for multiple reasons.

See more information

Shenzhen Yiguang Technology Co., Ltd. has launched the second-generation efficient and economical LS series LED driver power supply of 20W, 25W, 30W, 35W, 40W, 50W, and 60W, which is an improved version of the LPS series 0-10V dimming product.

See more information

Continued (1) High temperature step stress test results: Setpoint(°C)FunctionalTestResult(Pass/Fail)Notes+20PassSampleno.1wasappliedinthistest.+30Pass +40Pass +50Pass +60Pass +70Pass +80Pass +90Pass +100Pass +110Pass +120Pass +130FailTheLED

See more information