Yiguang Technology LED Driver HALT&HASS Test Conditions

1. Goal

The tested samples underwent HALT (High Acceleration Life Test) process to reveal weaknesses in their design, component selection, and/or process. During the HALT testing process, the samples are subjected to gradually increasing thermal steps, rapid temperature changes, vibration, and higher stress levels in a combined environment to determine the inherent defects of the samples.

2. HALT's experiment

The purpose of HALT testing is to help product designers create a more powerful and reliable product, thereby improving application reliability and reducing warranty costs. The product is subjected to a certain stimulus far beyond the expected on-site environment to determine its working and damage limits. Faults usually occur after being applied at much lower stress levels for a long time, and are quickly detected in a short period of time by applying high stress conditions.

The HALT experiment is mainly the process of discovering marginal conditions. In order to strengthen the product, it is necessary to know the root cause of each malfunction in order to determine and correct it until the basic limit issues of the technical product can be reached. This process will determine the widest possible margin between product functionality and the environment in which it will operate, thereby improving product reliability, reducing the number of on-site returns, and achieving long-term cost savings.

3. Experimental process

Conduct HALT test on the LED driver of an LED light board. During the testing process, the LED light board was placed outside the chamber.

Perform vibration, thermal step, and cold step tests on LED drivers to conduct stress tests with rapid thermal change rates. During the testing process, our goal is to find the operating and failure limits of the driver for this product under thermal step stress and vibration step stress conditions. Once these limits are determined, rapid thermal transition temperature and multi axis comprehensive environmental, 6-degree-of-freedom vibration stress testing can be conducted. Our goal is to address weak links and stresses, and even expand the scope as much as possible. The work and damage limits are summarized in Table 1.

Table 1 - Summary of Operating and Destruct Limits for LED Driver

| Stress Type | Chamber Set-point Level |

| Temperature LOL | -30°C |

| Temperature LDL | -50°C |

| Temperature UOL | + 120°C |

| Temperature UDL | + 160°C |

| Vibration OL | 60 Grms |

| Vibration DL | 65 Grms |

4. Conclusion

4.1 Temperature step stress

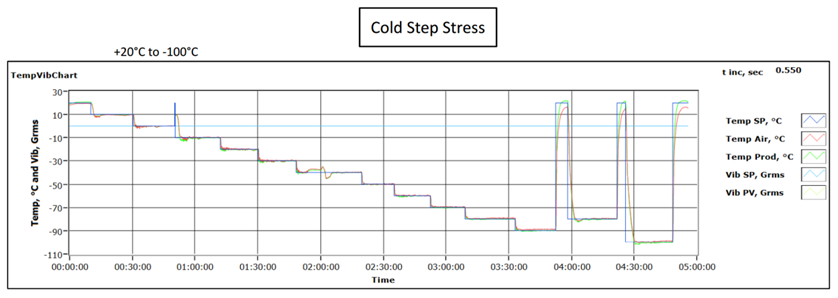

The system starts to perform cold and hot step stress at+20 ° C, and decreases the temperature by 10 ° C increments. Once the thermocouple (product temperature) reaches the set temperature and equilibrium of the product, maintain it for 10 minutes.

The system undergoes thermal step stress starting at+20 ° C and increasing at a temperature increment of 10 ° C. Once the thermocouple (product temperature) reaches the set temperature and equilibrium of the product, maintain it for 10 minutes.

Low temperature step stress test results

Setpoint (°C) | Functional Test Result (Pass/Fail) | Notes |

+20 | Pass | Sample no.1 was applied in this test. |

+10 | Pass |

|

0 | Pass |

|

-10 | Pass |

|

-20 | Pass |

|

-30 | Pass |

|

-40 | Pass |

|

-50 | Pass |

|

-60 | Pass |

|

-70 | Pass |

|

-80 | Fail |

|

-90 | Fail | At -90°C, the LED light panel lighted up with intermittent weak light flashes. |

+20 | Pass | It recovered at +20°C. |

-80 | Fail | The LED light panel lighted up with intermittent light flashes with normal light intensity. |

+20 | Pass | It recovered at +20°C. Cold operating limit was found at -70°C. |

-100 | Fail | The LED light panel lighted up with intermittent weak light flashes. |

+20 | Pass | It recovered at +20°C. Cold destruct limit was found at <-100°C.

|

End (1), continue (2).

Due to space limitations, only partial data will be uploaded.

More content can be obtained from the technical support of Yiguang Technology Company.