Starting from July 1st this year, LED light bulbs and LED light fixtures sold in the Japanese market must be affixed with a circular Product Safety Mark (PSE).

See more information

Test conditions for HALT&HASS of Yiguang Technology LED driver. 1. The samples tested by the target underwent HALT (High Acceleration Life Test) process to reveal weaknesses in their design, component selection, and/or process.

See more information

Continued (1) High temperature step stress test results: Setpoint(°C)FunctionalTestResult(Pass/Fail)Notes+20PassSampleno.1wasappliedinthistest.+30Pass +40Pass +50Pass +60Pass +70Pass +80Pass +90Pass +100Pass +110Pass +120Pass +130FailTheLED

See more information

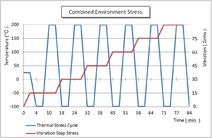

Continued (2) 4.3 Vibration Step Stress Test The vibration step stress is conducted at an ambient temperature of+20 ° C. The vibration step stress of the tested product remains at the set point of 5GRMS vibration value, with an increment of 5GRMS and a 10 minute dwell time interval. After 30GRMS, the vibration decreased to 5GRMS to determine if a fault had occurred, and was not detected at higher vibration levels. If there is no fault in the detection of resonance vibration, the vibration will increase to the next level.

See more information

Continuation (3) 5. Reliability improvement process 6. All testing process pictures have been completed. Due to space limitations, only partial data will be uploaded. More content can be obtained from the technical support of Yiguang Technology Company.

See more information

1. The concept of HALT&HASS testing, HALT (Highly Accelerated Life Test), originally means: High Accelerated Life Test; HASS (Highly Accelerated Stress Screen) originally means high acceleration stress screening. HALT&HASS is a test method for design quality verification and manufacturing quality verification extended by the US military, and has now become the standard product verification method in the US electronics industry.

See more information